I met Les Watts quite a few years ago now, while I was living in Chattanooga. He posted some stuff on the Micbuilders list, where I had lurked around looking for info about ribbon mics. Les was an engineer… he worked at Shure and did design work on the M97 cartridge, he had a bunch of patents, he designed and built the Polyribbon microphone. He was really, really smart, especially in terms of acoustics, electrical engineering, mic design, etc. But he had zero common sense… for example, most rational people would understand that smoking twelve hand-rolled cigarettes a day isn’t good for you, even if it is from organic tobacco that you raised yourself.

I drove over to visit him a few times in Tiger, GA. He had been married at one time, but was a complete bachelor when I knew him. His house was a wreck. But his machine shop was amazing, and he did some incredible work there.

He would call me occasionally. During these calls, he would talk- A LOT- about himself. About all the things he was going to do, about the patents he’d created, and how I was going to be his “marketing manager.” I knew enough to recognize that he was not somebody that you could depend on, and I DID NOT want to get entangled in any sort of business relationship with him. In the end, none of his grandiose business schemes ever materialized… at least while I knew him.

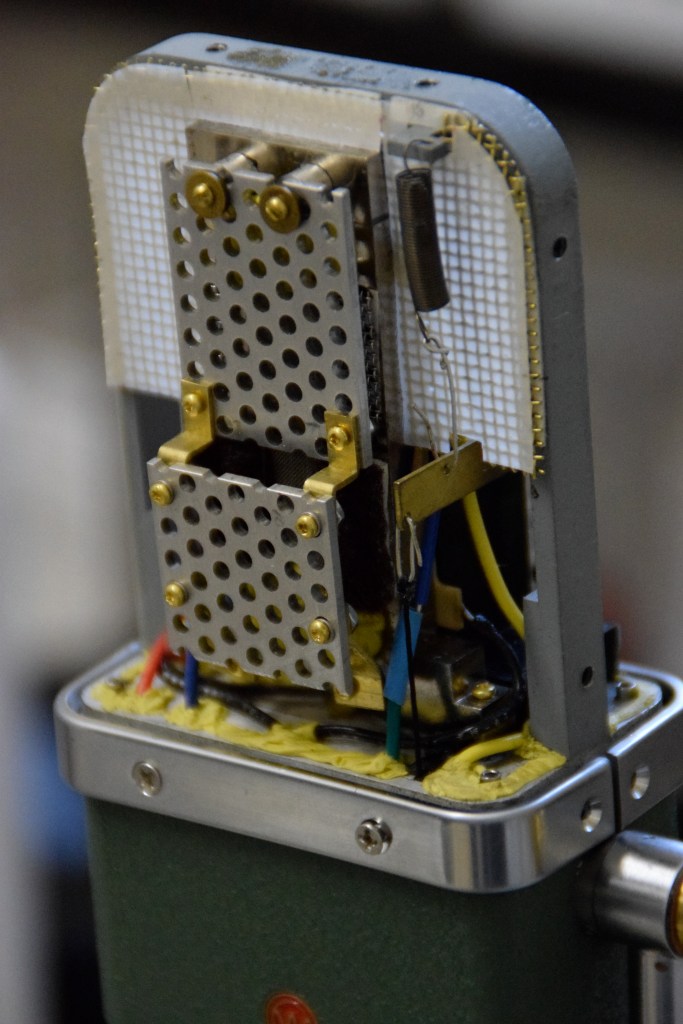

But… I remember very vividly the day when a large package arrived from Les. In it was a Polyribbon microphone. Les always talked a good story, but his follow-through was weak to say the least. He’d told me on numerous occasions about how he was going to send me a polyribbon, and about how it was the best-performing mic ever built. But I never expected that he’d actually send me one. But here it was, and it was absolutely beautiful. And it sounded beautiful too… except it didn’t have the rear rejection that I was expecting. You see, a polyribbon can be switched for different pickup patterns… bidirectional, cardioid, and omni. The old RCA 77DX had selectable pickup patterns as well, but the performance varied widely. Les’s design was different, in that it had a smooth high end response to 16k in all pickup positions, and the output was higher as well. Except for my mic, which was one of the first he’d built (in the end, he only built four mics. Two he sold to a guy in Saudi Arabia, one he had for himself, and I had one of the earliest ones.) This mic sounded fabulous in bidirectional mode, but the other two pickup patterns weren’t operational.

I drove the mic back to his place so he could have a look. He determined that it had been dropped during shipping, and one of the two ribbons became improperly tensioned. I watched him repair the mic… and that’s when I realized that, as good as it was, this mic would be impossible to reproduce at any sort of scale, It was just too touchy & required a good bit of luck to function properly. I remember that he got it to work, and carefully closed it up.

I still have this mic. I rarely bring it out of its custom case. It’s stored vertically, as a ribbon mic should be. I’ve used this on a handful of music jobs, but I don’t dare to use it unless a project warrants it.

And now that Les has passed away, I’m not likely to use it again unless Bonnie Raitt or Allison Krauss calls me up looking for it… and they don’t know me from Adam, so I don’t expect this mic will see much use. The ribbons in any ribbon mic are extremely fragile, and blowing into one is enough force to destroy it. And this mic uses two ribbons with a center clamp, differently tensioned. It really is an amazing piece of engineering artistry, and proved that he had the technical chops to back up his long-winded stories.

In all honesty, Les was a giant pain in the ass to deal with. He’d call and I’d be lucky to get five words out of my mouth during a hour long conversation. But for all his faults (and they were many and considerable) I miss him terribly. Maybe it’s because during our long talks, he treated me as though I was an equal. I wasn’t anything close to an equal, and admitted as much on numerous occasions. But it didn’t matter to Les. He was far and away more intelligent than I ever will be, and I guess in that sense he was kinda fun to talk to. But you’ll never meet a more stubborn, obstinate, dumbass genius no matter how far and wide you search. Even so, I wish he’d call me up again, with his great plans to start another mic company.

I hope he’s found his rest.

You must be logged in to post a comment.